Combat Monkey Build

Wingspan 750mm

Laser cut 5mm Foam Board $15

The kit includes:

- Foamboard airframe components

- Ply and popsicle sticks for the motor mount.

- Corflute fuselage underside

What you need to complete:

- 3 x 9g Mini Servos HXT900, MG90 etc

- Motor 2830 1200 kv to 2836 1500 kv

- 8x6 Prop (folding is better)

- 1300mah 3 cell lipo

- 30 amp ESC with BEC

- Sticky tape for hinges

- 3 control horns and 1.6mm piano wire

- 4ch RX

- Paper Party Streamers about 40mm wide and at least 5m long

Tools:

- Hot Glue Gun and Sticks

- Box Cutter

- Scrape pieces of foam board to wipe off excess glue.

- Z bender

Build

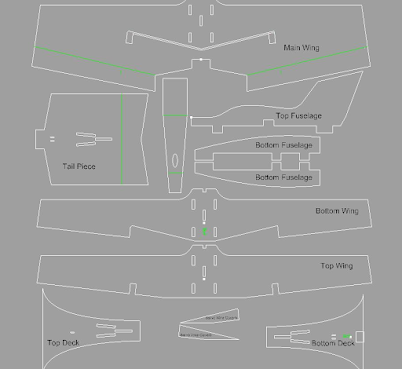

With a sharp blade release all the foam board

components from the backing sheet.

Carefully deepen the hinge lines on the ailerons and elevator without cutting right through then bend back to form a hinge. If you cut through, just tape the component back in place with clear sticky tape.

Bevel the rearward side of the hinge surfaces forty-five degrees with a blade or sandpaper block.Use clear sticky tape to reinforce the hinge lines from underneath. Note picture is incorrect 45 deg chamfer should be on the elevator and likewise the ailerons.

Using a glue gun with a good flow rate glue the Tail Piece to the Main Wing. This best done on a flat surface being careful not to glue the assembly to the building board. Tip: Keep moving the parts around to prevent gluing to the bench. Use a scrap piece of foam board to remove any excess glue.

Important : The Tail and Bottom Deck both have the letters ‘BOT’ (meaning facing down) inscribed on them. Check you have the correct orientation before gluing the top and bottom decks.

Take care that the slots are aligned between the sections.

Attach the Bottom Fuselage Silhouettes. The importance of aligning the slots is now clear. Pinch the end of the tabs between your fingers to make them easier to feed into the slots. Trim any proud tags flush with the surface.

Attach

the Top Fuselage Silhouette.

Construct

the motor mount assembly by gluing the four plywood sections together and

inserting the popsicle sticks. Use wood glue for this task. Ie PVA/Titebond. Trim the protruding sticks and sand flush.

Attach

the Corflute underside of the fuselage with tape at the rear and bend to form a

hinge. Align

the Corflute at the front.

Note

that the Servo Wire Covers have been placed in position for illustration

only. Tack these in place after the

servos have been installed.

Hot glue the servos in the wing and tack the Servo Covers in place. Fit control horns and push rods.

Screw

the motor to the ply Motor Mount using wood screws and attach the esc, receiver

and battery with Velcro.

Important : The center of

gravity should be 50mm from the leading edge of the wing.

We suggest setting up rates on all control surfaces and applying at least 30% to 40% expo.

Streamers are simply attached to the fin with sticky tape.

Comments

Post a Comment